Irrigation technology is expanding at a rapid pace, and to keep your customers informed, your knowledge of irrigation technology needs to grow too. There are new devices and tools constantly being developed. At times, it is overwhelming. As a salesperson, it is crucial to consider and compare all the options and determine which equipment would be the best for each application. But besides having the “best” option, a salesperson must understand how it works and install it. Products like valve controllers, soil moisture sensors, and weather stations are made to help farmers. Without proper installation, it’s useless equipment. The importance of technical knowledge in a sales role is remarkably high, which is why it gives an advantage to those in sales who know it and know how to use it. It means understanding the installation procedure, how to use the system, and how to troubleshoot it.

This goes from completely automated greenhouses down to small lawn sprinkler controllers. What happens if the system stops working? Does the customer know why it stopped working? More than likely, farmers will not have the time to investigate it themselves, let alone have any time. So, who will they call? Not Ghostbusters.

Installation

Proposing an automated system is more than just knowing what it does. It is also learning what it needs to operate and proper installation. Without experience, it is easy to overlook details such as weather conditions and pests. For some, this is trivial, but for others, this will be the first time they think of it. Unprotected wire and tubing may be at risk of being chewed on by rabbits or coyotes, which is why it is essential to have wire protection whenever possible.

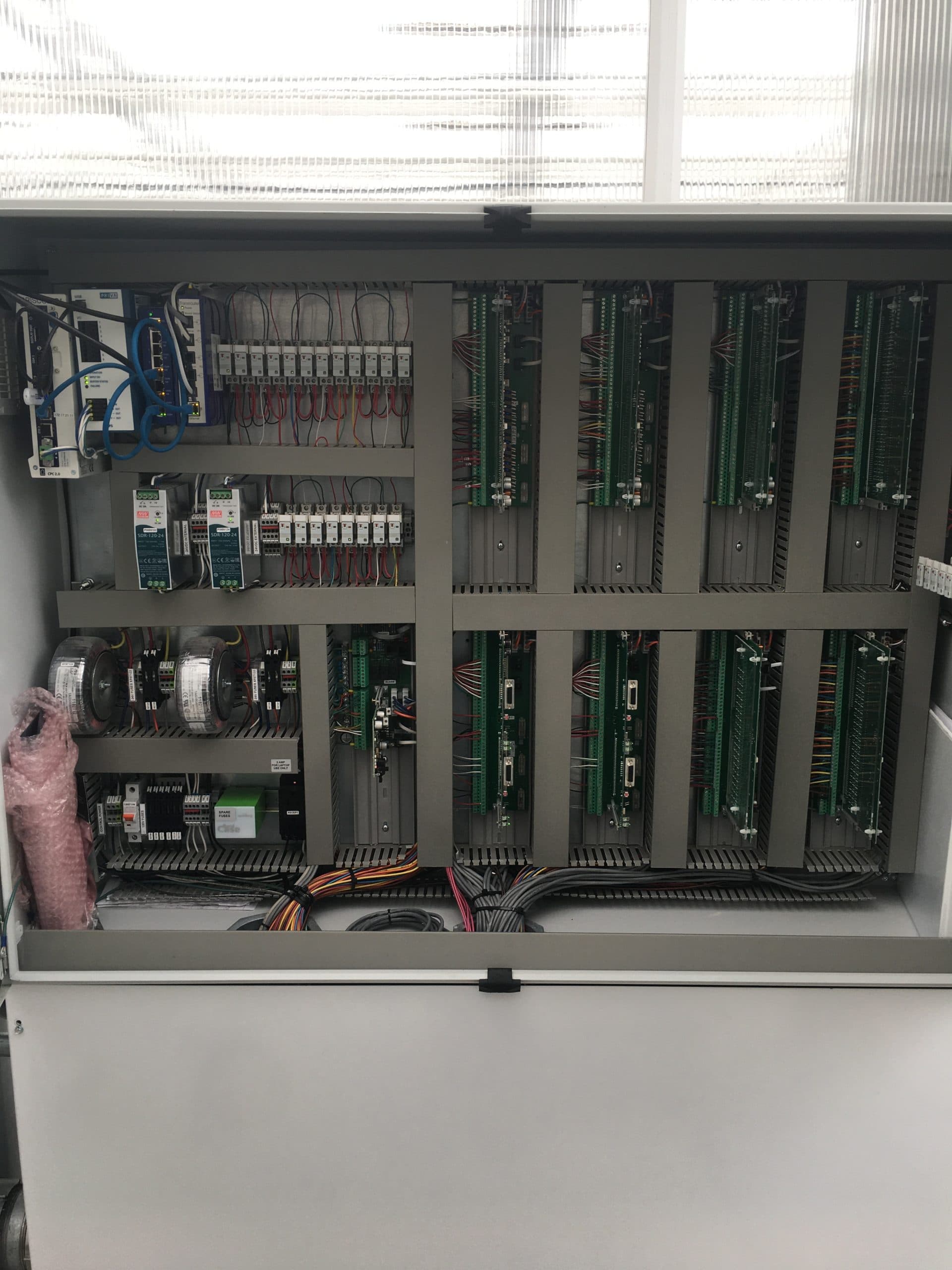

Proper planning is the key to a successful installation. Where is the controller mounted? Do you need to build a structure to hold it? If so, you need to account for hardware costs such as bolts, screws, concrete anchors, channel strut, tele-strut, and conduit. Are you using high voltage equipment like lights, vents, and heaters? If so, you must build a control panel with the right components.

Many of today’s systems use radio communication between control points, so it is important to understand how radio waves travel. This is important to know when there is a tree line or structure that could potentially put a restriction on communication. Thinking about these items and planning appropriately will save hours in the field and make your job more profitable.

Wiring and Commissioning

The complexity of wiring and commissioning will vary from system to system, depending on the equipment used. Although manufacturers will provide wiring diagrams, it is still essential to understand the language used. By language, I mean knowing what acronyms like AI, DO, NC, and NO mean. Do you know what time of input your sensor should be wired to? Or what type of output your valve or relay should be wired to? Does your wire need to be shielded? Do you know why it needs to be protected? These are just a few questions that should be answered throughout the process of designing an automated system.

Commissioning a system is time-consuming. For systems with solely valve control, it is easy to assign an output to a valve. However, it is essential for systems with different sensors to know what information your system needs to use those sensors. For example, hydrostatic pressure level sensors measure the level of a tank, which has a varying electrical resistance that changes with the pressure exerted on them. You can measure a change in voltage in a circuit with a constant current and a variable resistance. This is an example of calculating a 0-5V signal. This is important because you need to calibrate the system to know which voltage corresponds with an empty tank and which voltage corresponds with a full tank.

Troubleshooting

Troubleshooting an automated system can be difficult and distinguishes a salesperson who knows the equipment from one that sells it. This is where technical knowledge and logic come into play. There could be multiple reasons why a solenoid controlled, hydraulically actuated valve will not open. Maybe the controller short-circuited? Check its voltage. Perhaps a mouse or gopher chewed through the wire? Check continuity in the wire. Maybe something is stuck in the valve and preventing it from opening? Look inside. There are many more things that may need troubleshooting, and the best thing you can do is be prepared. Understand the wiring, understand the installation, and understand the software.

Conclusion

As more options become available, it is crucial to research them. These tools and devices are made to provide a solution, not be the problem. Some will work, and others will not. It is up to us to determine which will fall in which category. Understanding the wiring, the installation, and the operations will make it easier to decide which systems and devices are worth presenting to your clients.