Type 375 Ball Valve

$33.00 – $266.66

The Type 375 is a rugged and reliable midrange industrial ball valve that is designed specifically for open/close manual service. It is fully serviceable and features a redundant stem seal, blowout proof stem and utilizes a floating ball design.

Product Description

The Type 375 Ball Valve shall be true union and utilize a floating ball design. The ball shall be full port with two way blocking capability. The stem shall be blowout proof and utilize a double o-ring seal. The seat carrier shall be adjustable with the handle doubling as a seat carrier adjustment or removal tool. Ball seats shall have an elastomeric backing o-ring and all elastomeric seals shall be of like material. ANSI flanged versions shall meet the ANSI B16.5 150lb standard. All valves shall be tested in accordance to ISO9393 and designed to ISO16135 standards. All valves shall be manufactured under ISO9001 for Quality and ISO14001 for Environmental Management. PVC valves shall meet ASTM D1784 cell classification 12454 standards. CPVC valves shall meet ASTM D1784 cell classification 23447 standards. PPn valves shall meet ASTM D4101 standards. Valves of all materials shall be RoHS compliant.

General

- Size: ⅜”–4”

- Material: PVC, CORZAN® CPVC, or PPn

- Seat: PTFE

- Seals: EPDM or FPM

- End Connection: Solvent cement socket, threaded, flanged, PPro-Seal™ electrofusion socket

- Standard Pack Quantity: 1 valve

Key Certifications

- NSF 61: PVC and CPVC

- USP 25 Class VI (physiological non-toxic): PP

- FDA CFR 21 177.1520: PPn

- CORZAN: CPVC

Optional Features

- Vented Ball: For sodium hypochlorite use

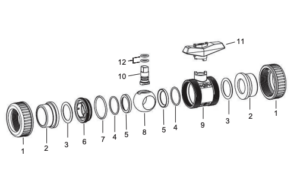

Components

Key Design Features

An arrow is molded on the body of the Type 375 to indicate the side of the valve with a fixed seat. The valve is bidirectional, so the installation direction does not affect the valve’s performance. However, the installation direction of the fixed side of the valve does provide benefits for both upstream and downstream installs. When a valve is closed, the ball seal in a pressurized system is provided by the downstream seat, it is therefore advantageous to install the valve with the fixed side downstream. Depending on system design, it can be easier to adjust the seat carrier of a valve if the fixed seat is upstream because the upstream side of the valve does not need to be depressurized.

Additional Information

| Size | 1/2", 3/4", 1", 1-1/4", 1-1/2", 2", 3" |

|---|

Only logged in customers who have purchased this product may leave a review.

- No merchandise may be returned without prior authorization and issuance of a return authorization number from IDC.

- Credit will be based on invoice price.

- A restocking fee of 20% (twenty percent) will be assessed on all returned goods unless a return occurred due to IDC’s error. Returned goods shall be shipped prepaid by Buyer and received in resalable, new condition before credit will be issued.

- All returns are subject to inspection by IDC. Buyer will be billed for any freight charges incurred by IDC unless pre-approved by IDC and/or returned due to an IDC error.

- No returns are accepted after 60 days.

Reviews

There are no reviews yet.